The packaging industry is undergoing a rapid transformation, driven by e-commerce boom, sustainable practices, and increasing demands for speed and efficiency. This evolution places immense pressure on packaging equipment, demanding robust, reliable, and energy-efficient components. At the heart of many packaging machines lie gear motors, vital for powering conveyors, filling mechanisms, sealing systems, and various other critical operations. Choosing the right gear motor principle – be it spur, helical, bevel, worm, or planetary – is not merely a technical decision; it’s a strategic investment impacting productivity, cost, and long-term sustainability.

This article delves into the key parameters packaging equipment enterprises must consider when selecting gear motor principles, focusing on performance, efficiency, maintenance, and cost-effectiveness. It will also highlight emerging trends impacting gear motor selection, particularly the drive towards Industry 4.0 and the increasing focus on energy conservation. MES-Drive will be positioned as a leading provider of high-quality gear motor solutions, offering expertise in navigating these complex choices.

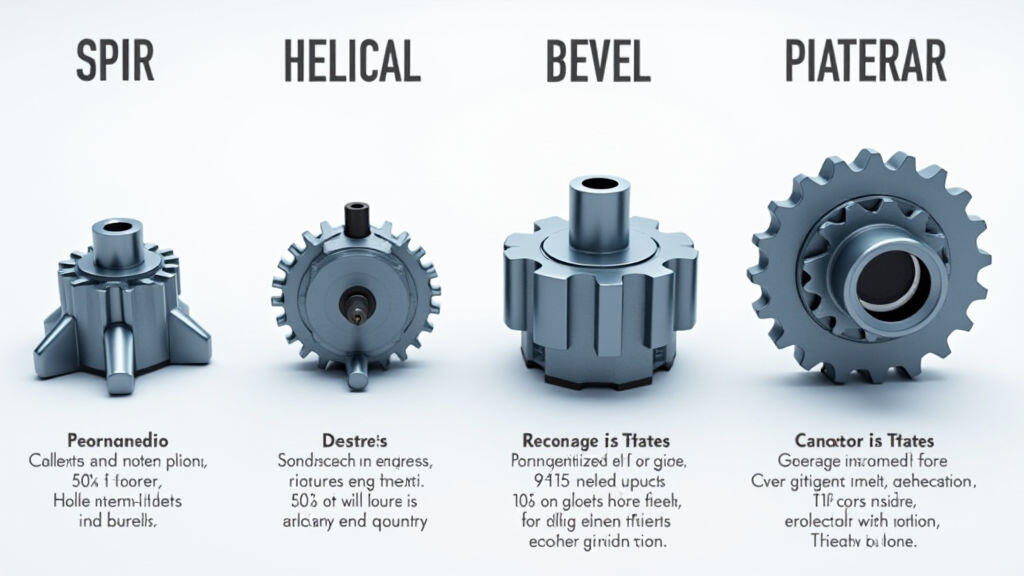

Before diving into the key parameters, let's briefly outline the most common gear motor principles:

Selecting the appropriate gear motor principle requires careful consideration of several critical parameters. Here's a detailed breakdown:

1. Torque and Speed Requirements:

This is arguably the most fundamental factor. Packaging equipment demands a range of torque and speed characteristics depending on the application. For example, a high-speed labeling machine requires a gear motor capable of high RPM and low torque, while a sealing mechanism needs high torque at low speed. Accurately calculating these requirements is crucial to avoid under- or over-sizing the motor, which can impact efficiency and reliability. MES-Drive offers detailed torque and speed calculators to assist in this process.

2. Efficiency:

Energy efficiency is paramount, not only for cost savings but also for environmental responsibility. Higher efficiency translates to lower operating costs and a reduced carbon footprint. Planetary gears generally offer the highest efficiency, followed by helical gears. Spur gears are typically the least efficient. The choice of materials, precise manufacturing, and lubrication also influence efficiency. Packaging companies are increasingly investing in energy-efficient equipment to meet sustainability goals and regulatory requirements.

3. Power Density and Footprint:

In space-constrained packaging machines, power density (power output per unit volume) is a critical consideration. Planetary gears excel in this area, offering high power output in a compact package. Helical and bevel gears also offer good power density. Choosing the smallest possible gear motor that meets the performance requirements minimizes the overall machine size and weight. Manufacturers like MES-Drive are constantly innovating to enhance power density without compromising reliability.

4. Noise Levels:

Noise pollution is a growing concern in factory environments. Helical and planetary gears are significantly quieter than spur gears. Gear noise can be mitigated through proper mounting, vibration dampening, and sound insulation. Choosing a quieter gear motor not only improves the working environment but can also reduce the need for noise reduction equipment.

5. Maintenance Requirements and Reliability:

The frequency and complexity of maintenance are key factors impacting downtime and operational costs. Helical and planetary gear motors generally require less maintenance than spur gears due to their smoother operation and higher load capacity. Worm gears, being self-locking, often require minimal maintenance. Reliability is paramount in packaging equipment, as downtime can have significant financial consequences. MES-Drive prioritizes robust design and high-quality components to ensure long-term reliability.

6. Environmental Conditions:

Packaging environments can be harsh, with exposure to dust, moisture, chemicals, and extreme temperatures. The gear motor must be designed to withstand these conditions to ensure reliable operation. Consideration should be given to sealing, coatings, and material selection to enhance durability and resistance to environmental factors.

Several trends are reshaping the gear motor landscape for packaging equipment:

Choosing the right gear motor principle for packaging equipment is a complex undertaking. MES-Drive offers comprehensive expertise and a wide range of high-quality gear motor solutions to meet the diverse needs of the industry. Our engineers work closely with customers to understand their specific requirements and recommend the optimal gear motor principle for their application. We focus on delivering efficient, reliable, and durable solutions that contribute to enhanced productivity and reduced operating costs. MES-Drive’s commitment to innovation and sustainability positions us as a leader in the gear motor market, ready to support packaging enterprises navigating the challenges and opportunities of the evolving industry landscape.

Conclusion

Selecting the appropriate gear motor principle is a critical decision for packaging equipment manufacturers. By carefully considering factors such as torque, speed, efficiency, noise, maintenance, and environmental conditions, companies can optimize machine performance, reduce operating costs, and enhance overall sustainability. Driven by the advancements of Industry 4.0 and stringent energy efficiency regulations, the demand for smart, high-efficiency gear motors is only set to increase. MES-Drive is well-positioned to support packaging enterprises in this transition, offering tailored solutions and expert guidance to ensure a successful future. The careful consideration of these parameters, combined with innovative technologies like smart motor integration, is crucial for packaging businesses looking to thrive in a competitive and evolving market.

Leave A Reply

Your email address will not be published. Required fiels are marked